technic expert mechanical electrical engineer, and has general designed capacity in machine equipments area.

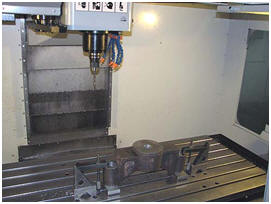

Under the Shanghai Economic committee's help in 2007, for the company's project development, import the equipment for production in the project successfully, the major equipments are vertical machine center with 1372mm*635mm table and horizontal machine center with 500mm*500mm table that made in USA.

Except above this company also has Japanese quality control pattern completely department. The company batch product's quality control continues to use Japan pattern completely, simultaneously company best quantity control system also obtained foreign capital enterprise's approval, has formed the good partner mutually. At present, undergoes the inspection, the American metal products interlink LLC also thought that Our company had has produced the high accuracy components for their company ability, now is trying to make the sample, once after the confirmation may the volume production.

This company has experience in overseas enterprise order form for many years, in CAD production and then assembles to export etc., for the overseas enterprise's complete set of products with parts and assembles cooperation, had already formed by this company production processing and the cooperative production chain, namely from semifinished materials gathering, by the machine-finishing, simultaneously may carry on the surface treatment, including the painting, plates models.

This company specialize in the project is as follows:

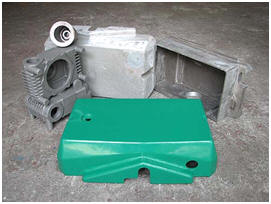

The precise pouring casting (Loses the wax casting) parts, the material may be the carbon steel, the stainless steel, the nodular cast iron and so on, in the picture the parts biggest 600 g.

Generally the pouring casting (cast steel), the material may be the carbon steel, the alloy steel, the stainless steel, the parts biggest 1.5 T.

Hammers, the maximum weight is 1.5 T, its material aluminum alloy, the alloy steel, each kind of carbon steel, can supply the cooperation working, the single weight begins 100 g.

Each kind of founding, the maximum weight is 500 kg, the material may be the nodular cast iron, the gray iron, the aluminum alloy.

The aluminum alloy presses the casting, has 500 T and the following press.

Middle and small scale structural element, single unit in 500 kg.

Vertical Machining Center Table size is 1372 mm × 635 mm, max weight on table (evenly distributed) 1588 kg, accuracy (1 axis) ±0.0025 mm.

Horizontal Machining Center is double table, table size is 500 mm × 500 mm, pallet changer max pallet load 454 kg, accuracy Repeatability ±0.0025 mm, because this equipment is the double work table, suits batch product loading and unloading not conveniently, and uninterrupted work.

Number obviously milling machine made in Beijing X:900 mm,Y:260 mm,Z:300 mm.

Number obviously milling machine made in USA X:975 mm,Y:415 mm,Z:490 mm.

Numerical control lathe CK6150L-750

In summary is this company the work content which operates at present. We through our successful experience until now, always for customer requirement to let customer satisfaction on the product quality, the price and the date of delivery, simultaneously we really sincere hope more foreign capital enterprises are also willing to establish the new partner relations with us, this company insists make customer satisfaction and the trust as management objective.